The resilience of nuclear power plants is a cornerstone of energy stability and safety in the modern world. With evolving challenges in the energy sector, predictive maintenance technologies are becoming a game-changer for improving the reliability and efficiency of nuclear facilities. By identifying potential issues before they escalate, predictive maintenance ensures optimal performance, minimizes downtime, and significantly enhances the safety of operations. These technologies empower operators with data-driven insights, enabling smarter decision-making and proactive management.

The Role of Predictive Maintenance in Nuclear Plant Resilience

Predictive maintenance leverages data-driven insights and advanced technologies to proactively predict and address equipment failures. This approach differs from traditional reactive maintenance, where actions are only taken after a failure occurs. By implementing predictive maintenance strategies, nuclear plants can benefit in several ways:

- Improved Safety: Early detection of potential failures reduces the risk of catastrophic incidents, ensuring a safer environment for workers and nearby communities.

- Increased Efficiency: Continuous monitoring and timely interventions optimize the performance of critical equipment, leading to better energy output.

- Cost Savings: Preventing unexpected equipment failures minimizes repair costs and reduces financial losses associated with unscheduled downtimes.

- Prolonged Equipment Lifespan: Predictive maintenance helps maintain equipment in optimal condition, extending its operational life.

- Regulatory Compliance: Adopting predictive technologies ensures adherence to industry regulations and standards, reducing the risk of penalties or shutdowns.

Key Technologies Powering Predictive Maintenance

Advancements in predictive maintenance technologies have transformed how nuclear plants operate. These technologies combine cutting-edge tools and innovative methodologies to create a more resilient infrastructure. Some key technologies include:

- IoT Sensors and Real-Time Monitoring: Internet of Things (IoT) sensors continuously monitor critical components, providing real-time data on temperature, pressure, vibration, and more. This data is analyzed to detect anomalies that might indicate potential failures like reactor overheating, turbine imbalances or inefficiencies, coolant system leaks or failures, degradation in electrical systems, and structural vulnerabilities in containment systems.

- Artificial Intelligence and Machine Learning: AI-driven algorithms analyze historical and real-time data to predict when and where equipment failures might occur. Continuous learning allows machine learning models to refine their insights, achieving greater precision with every update.

- Digital Twins: Digital twin technology creates a virtual replica of nuclear plant components, enabling operators to simulate different scenarios and predict outcomes without risking real-world assets.

- Big Data Analytics: Advanced data analytics tools process large datasets to identify patterns, trends, and correlations that human operators might overlook. These insights inform predictive maintenance decisions.

- Cloud Computing: Cloud-based platforms facilitate centralized data storage and processing, making integrating predictive maintenance systems across multiple facilities easier.

Strategic Steps for Implementing Predictive Maintenance in Nuclear Plants

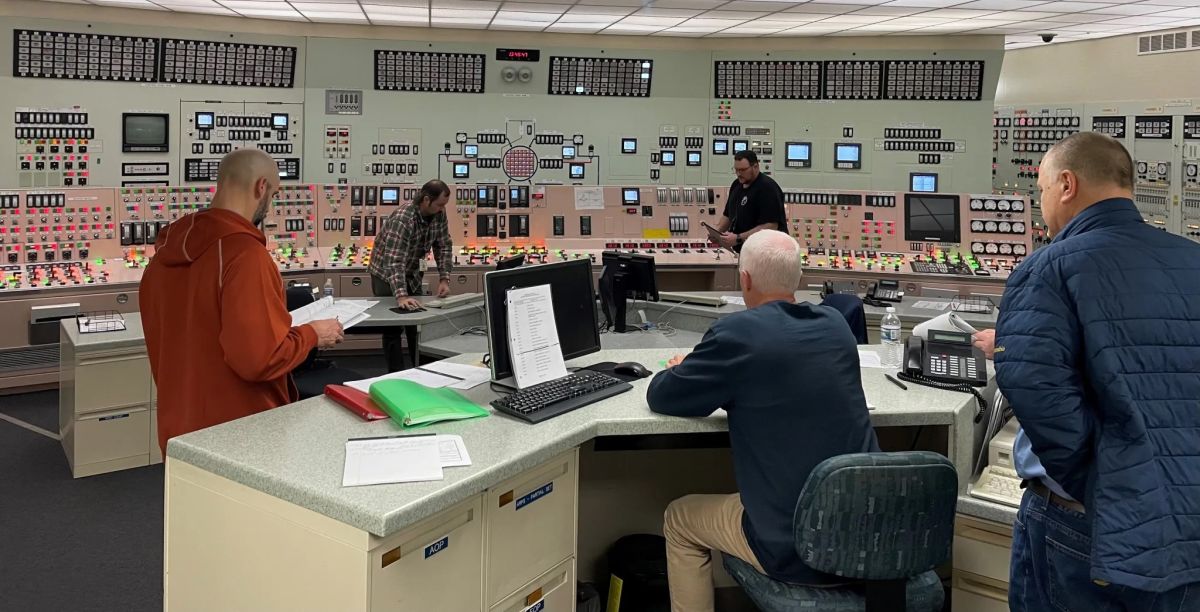

Implementing predictive maintenance technologies in nuclear plants requires a strategic and well-structured approach to ensure effectiveness and long-term benefits. The process begins with assessing the current infrastructure to evaluate existing equipment and systems, identifying areas where predictive maintenance can add significant value. Once these areas are identified, selecting the appropriate technologies that align with the plant’s specific needs and operational goals is crucial.

Empowering personnel with the skills to navigate predictive maintenance systems is crucial, enabling them to unlock the full potential of these cutting-edge technologies. Integration of predictive maintenance technologies with the existing plant infrastructure must be seamless to ensure optimal performance and minimal disruptions.

Finally, the performance of these systems should be continuously monitored and optimized based on operational feedback, enabling ongoing refinement and improved outcomes over time. This comprehensive approach ensures that predictive maintenance technologies are fully utilized to enhance the resilience and reliability of nuclear plants.

Conclusion

Predictive maintenance technologies are revolutionizing the nuclear energy sector by enhancing plant resilience, reducing operational risks, and ensuring sustained energy production. As the industry moves towards more data-driven solutions, adopting predictive maintenance is necessary for long-term sustainability and safety. By leveraging advanced technologies such as IoT, AI, and digital twins, nuclear plants can pave the way for a future where reliability and innovation go hand in hand. By adopting these tools, the nuclear industry can effectively address unexpected challenges while positioning itself to meet the rising global energy demand.

Disclaimer: Any opinions expressed in this blog do not necessarily reflect the opinions of Certrec. This content is meant for informational purposes only.